One of the big projects last summer was “Pergola/patio that was installed on the west end of my workshop. While all that was going on, I poured a cement pad for a small addition to be added to the shop. This was to be for my garden tools. I was getting itchy for an “outside project” so I began work on this addition on Wednesday.

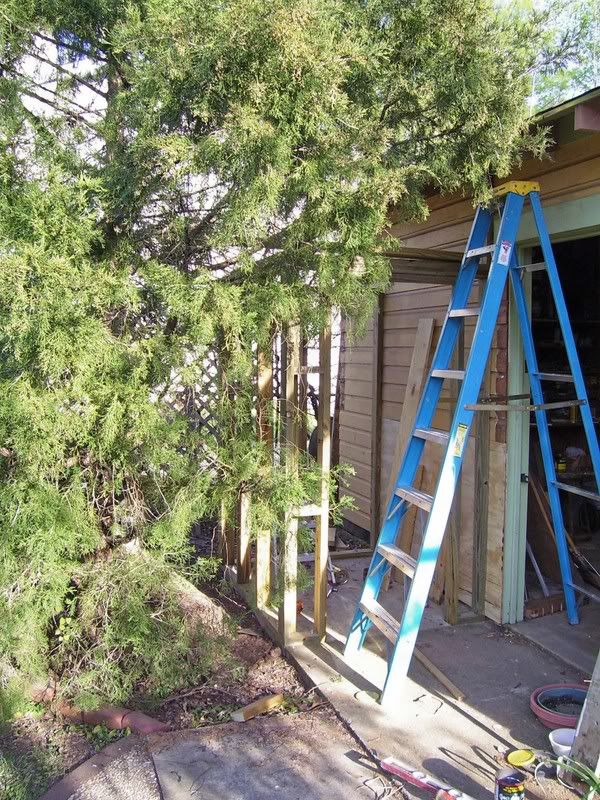

This side of the workshop faces north. It is always in the shade. I installed a new doorway and poured a cement pad to this back in 1999. There was a great deal of rotten siding that had to be replaced. I think there is some source of water in this area. The cement floor in the workshop on this side is always damp. Here it is only eight years after the fact and again I have to replace rotted siding. About three feet going from the bottom up of the siding is removed. The bottom three boards are pretty well trash. The rest is not in that bad shape. A piece of 23/32 sheeting is installed where the siding would be inside the new garden shed. From the outside of the shed to the edge of the workshop, the removed siding is fitted in. The bottom-most piece is coated on the back with Minwax Wood Hardener. Hopefully that will help stop the capillary action of water soaking into the wood.

I have a pretty general idea how this is supposed to all flow together. The first job in the framing department was to anchor the sill plates to the foundation. When I poured the cement last year, bolts were put in place for this task. It was a simple job to measure, cut, drill and install the pressure treated lumber.

From here it is just putting up the framing. This is a bear of a job to do solo. It is up and down the ladder, measuring, cutting, leveling and nailing for pretty much the whole day.

It is not till I get pretty well finished with the framing of the walls that I figure how I will install the roof. I will scab this shed roof onto the existing garage roof. The same roof I redid last summer! UGH!! I will have to add a little bit to the headers to raise the height so the new rafters will be at the same angle. It is going to be some tricky work to get this “scabbing” to even out and look right. That is going to be my project for today…..install the rafters.

I was half way thorough this entry when I had to shut it down at 6:00 a.m. for the Friday walk at the University with Debbie. The campus is so beautiful. I remembered to take the camera. Following are some pictures as to how I started my day……

With it being Friday it was “coffee day” at the Starbucks on campus. We got there a little later than usual. It was so busy! There must have been complaints because the music was a wonderful soft Jazz, and the staff was friendly and nice! Rusty was in his spot over in an upholstered “lounge chair” in the corner. Debbi and I made his day! He always knows when it is Friday when we show up!

This is a view of "The Quad" at 7:00 a.m. on 3/23/2007 facing south east.

This is the Gorgas House on campus. It is one of the few structures of the original college to survive the destruction inflicted by Union forces in the last days of the "late unpleasantness".