There is a term in house restoration called “the mushroom effect”. I think I’ve touched on this subject before. It is when a minor project evolves into a huge undertaking. That is what I’m in the middle of. UGH!!

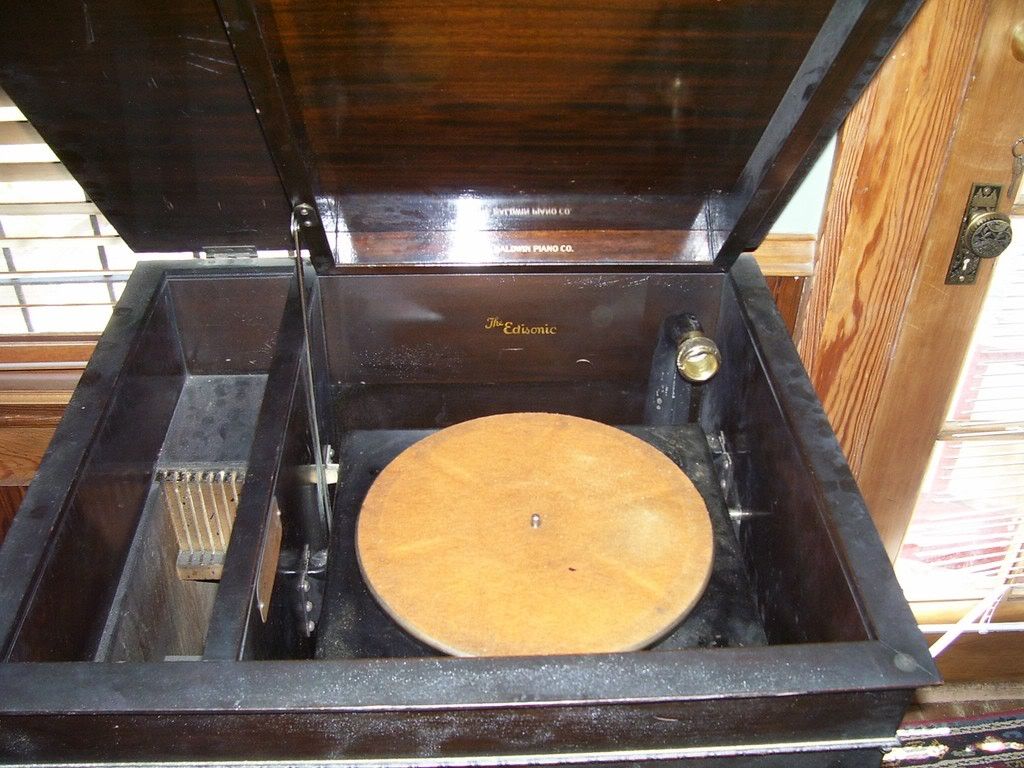

This current phonograph restoration project was SUPPOSED to be just a cleaning up of the case and installing a new grill cloth. WRONG! The reproducer rebuild required a new diamond stylus. This was easy enough to order. But, to fit onto this late style head I needed to install a hook underneath the needle that attaches to a small tension spring. Again that is no impossible task.

Before electronics entered the sound reproduction scene, the sound waves recorded into the record groove were recreated mechanically. The Edison system utilized a “hill and dale” method where-by the record groove went “up and down” as opposed to the “lateral” method where the sound waves were recorded going "side to side" used by Victor and the other major record producers. A parallel comparison to this would be the battle between Beta and VHS video tape systems in the 1980’s. Technically Beta was the better system (as was "hill and dale), but because of poor marketing and business decisions by Sony it eventually lost out.

*I have to interject here… my good friend Donald was one of the first people I knew to have a tape system. He used to say..”Oh, I have a Betamax!” Talk about dated. Today, that sounds almost as obscure as me saying, “I have a Victrola!”

The needle in the groove transfers the information to a diaphragm which vibrates and is then amplified through a horn. That is the reason for the old records rotating at 78 rpm. That surface speed generated enough energy to the needle to properly recreate what had been recorded. In the Edison system for his disc players a woven silk link is used to connect the needle to the diaphragm.

After nearly 80 years these linkages are getting pretty worn and frazzled. (Hey that sounds like me!!) On this particular reproducer I’m working on, the link was almost broken through. A little bit of super glue is just what the doctor ordered. That repair worked fine until I happened to twist the damn thing installing the needle, where by it just snapped off.

Pretty much my Sunday was spent dismantling the diaphragm assembly and making up another linkage. It was pretty much one frustration after another. This aggravation is a reminder to me why I refuse to take work in from other people!

I worked out a system to where I first drilled out the fabric from the old linkage. From there I was able to open up the crimped housings and fish a new piece of woven material through. Through researching various message threads on a restoration site I learned the perfect replacement “string” can be obtained from “decorator tassels”. I have only one of those annoying things that came with a novelty music box I purchased a long time ago. Crazy as it sounds, it worked perfectly!

That was pretty much my Sunday.

Monday morning was spent at the bench making up the connector linkage for the diaphragm. A tiny threaded rod is screwed into an ivory button and then shellacked into place. I had one snap in half when I attempted to remove it. Nothing left to do but make up another one. It is not like you can go to a hardware store and buy any of this crap! Working under such tiny close tolerances is very draining. Figuring out the techniques with nothing to go by can be very frustrating. The next one I have to make will be much easier! Once it was done, I walked away from the bench. You have to know when to quit!

The double mainspring assembly should be here soon. It will be so nice to work with big things again! Everything is going to get torn apart, then cleaned and regreased/oiled. The best mainspring grease is 40% flake graphite and 60% Vaseline. I stopped at an auto parts store figuring if any place would even know what graphite was they would. They had never heard of flake graphite.

Once again I was saved by the internet. I have two pounds of #2 Flake graphite en route to me. I figure it is cheaper to pay the shipping over driving untold miles and getting aggravated. I get so tired of the pained looks I get trying to track down things nobody has ever heard of!

This morning I’ll apply a coat of oil finish to the phonograph case to see if I can breathe some shine into that alligatored finish. It all cleaned up pretty nice, but it was a junky/cheap cabinet to begin with, so I’m not expecting miracles!

Then I have to be in Greensboro for a memorial service at 11:00 a.m. My good friend Buck lost his son Edward last week. Edward was only 36, but let’s just say he had problems that cut his life short. Buck had told friends he had written him off years ago and been expecting his death for some time. That is so sad, but people have to take responsibility of their lives.

Enough of this sad and depressing stuff… time to feed the birds, fix my last cup of coffee, and then work on that cabinet…..