If I remember correctly the song “Time Warp” from The Rocky Horror Picture Show starts….. “It’s astounding, Time is fleeting…Madness takes it’s toll”. How true: time has just been flying by for this boy, and as far as being mad goes…. I think I’ll plead the 5th on that one!

People who really know me have seen me become consumed by a project. This latest patio mess is no exception. Monday found me making plans for a fast road trip to

I got on the road Tuesday morning at 3:50 a.m. It is a straight shot west on I-20 to

It was about 185 miles later I pulled off the road at exit 8 off I-20 at the Motel Six. The nicest woman checked me in. she had so much personality. I had her laughing so telling of this latest brick run. I made arrangements for a 4:30 wake up call the next morning. I really had her going when I told her I can’t wait to get my wake up call from Tom Bodett telling me I won the one million dollars! (That is the usual recording on the motel Six wake up call!!)

A “Catfish House” is just down the road. A take out catfish dinner and some cold Buds made for a great dinner to this road weary boy.

My wake up call is right on schedule…A woman’s voice tells me this is my wake up call.

Brick: Wait a minute, where’s Tom Bodett telling me I got a million dollars?

Woman: Hearty laughter…Oh baby I don’t have one million for you!

Brick: Laughing back…thanks, I’ll drop the key off on my way out….

What a nice way to wake up with laughing! I just love it when I get called “baby and Hun” in these situations.

I’m fine driving till I get to Jackson, MS. There were horrible thunderstorms I drove through. Even with all that weight I can feel the truck hydroplane on occasion. This is white knuckle driving. Mercifully the traffic is going slow in the right hand lane so I stay to the right.

I finally drive out of the worst of it and don’t have rain again till I get to the

It was 11:15 when I walked in the door to be greeted by Daggy and Stumpy.

By 1:30 p.m I had the truck unloaded and the bricks piled up.

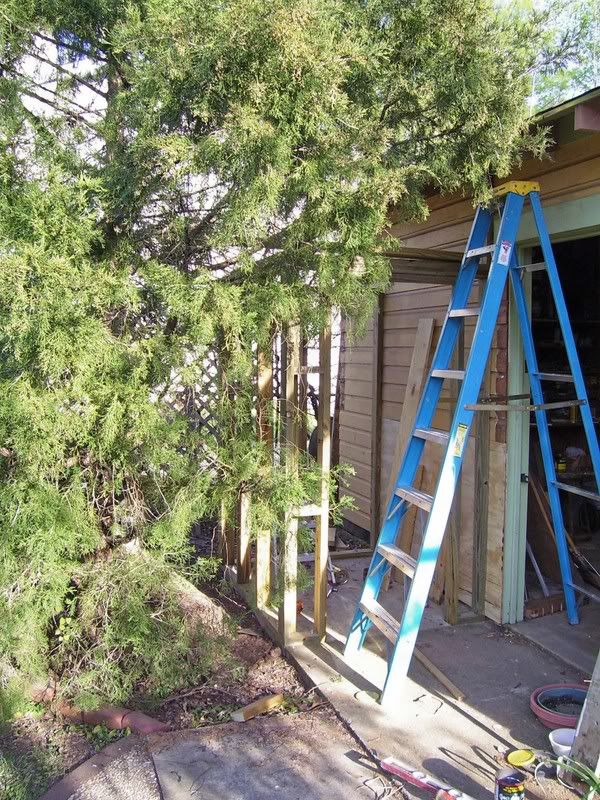

Thursday: The morning is delightfully cool: The perfect weather to get the ground ready for the new bricks. The hard clay is scraped and leveled. In one spot the ground is spongy. I dig down and discover the decaying remains of the tree that was destroyed back in 2000. The remains of the trunk and heavy side roots have to be dug up. UGH! This really heats me up and puts be behind time wise. Better to do the work now and have a good foundation than to skip the job and then have the patio “sinkhole” in a few years.

Time to load the truck up again: a short drive to Scotties for a load of crushed limestone. His business must be dong well. The yard is immaculate. I notice the bin containing the crushed limestone I need is nearly empty. He loads up a half yard into my little truck and the back end is back down to the ground!

That is unloaded and I need another ¼ yard to finish up: Another trip, another load of limestone. By the time I finish cleaning that mess off the truck I’m all done in.

Tamping down the crushed limestone.

But now I need to get the yard all detailed for the dinner party Saturday: I forgot to mention that one! I think everyone has a dish they know will always turn out and people love. That meal for me is bar-b-que lamb shanks. It was a standard dinner that my friends always looked forward to having. It has been some ten years since I cooked up that dish. The biggest problem is finding the lamb shanks to begin with. Publix markets has been carrying them. In the past few months I had acquired enough in my freezer to justify a dinner.

It makes no sense to just cook up a few, so I waited till I had even dozen shanks. I call the gang and everything is set for Saturday night. I told them to arrive around 5 and we will eat at 6:30 or so. The stove heats up the kitchen so; summertime is not the time to cook up a dinner like this. But I need to use these shanks up. I’m hoping cocktails and munchies can be out on the patio or front porch so the heated up house won’t make that much of a difference…

After the walk this morning I began the preparation of the shanks. They are first seasoned with salt, pepper, and paprika. Then they are browned in bacon grease using a cast iron frying pan. A sauce is made up using catsup, water, dry mustard, brown sugar, vinegar, and sliced onion. The shanks are arranged in a turkey roaster, the sauce is dumped over and the entire mess is slow cooked at 300 for a couple hours.

The secret is to have the shanks “rest overnight” to really soak up the flavor of the sauce. That also gives time to “defat” the sauce. Now the shanks and sauce just have to be warmed through for the dinner. When I have company over I hate to have to spend all my time in the kitchen!

Here are the shanks. Time to get them taken care of and get started on making the cheesecake for desert….